shreeshyampolyfilms01@gmail.com - GST NO. : 08BFEPJ9714A1ZO

| Business Type | Retailer, Trader, Distributor |

| Country of Origin | India |

| Material | Bopp, BOPP METLIZE |

| Thickness | 15-30 |

| Click to view more | |

Product Details

Application

Packaging

Color

Silver

Type

Bopp Heat Sealable Film, Roll

Roll Width

35 Inch

Payment Terms

D/P

Packaging Details

"BoPP Metallized HST" refers to a type of plastic film used extensively in packaging. Let\'s break down what each part means:

* BoPP (Biaxially Oriented Polypropylene): This is the base material. Polypropylene is a thermoplastic polymer. "Biaxially Oriented" means the film has been stretched in two directions (machine direction and transverse direction) during its manufacturing. This stretching process significantly enhances its mechanical properties, such as tensile strength, clarity, stiffness, and barrier properties.

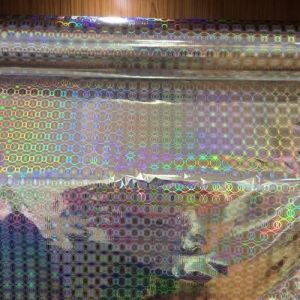

* Metallized: A very thin layer of metal, typically aluminum, is deposited onto one side of the BoPP film. This metallization process gives the film a shiny, silver-like appearance and, more importantly, dramatically improves its barrier properties against moisture, oxygen, and light. This extended barrier helps to increase the shelf life of packaged products, especially food items.

* HST (Heat Sealable): This indicates that at least one side of the film can be sealed by applying heat and pressure. This is crucial for creating secure pouches, bags, and other packaging formats that maintain product integrity and prevent tampering. Often, one side is heat-sealable, while the other side is treated for printing or lamination.

Key Properties of BoPP Metallized HST Film:

* Excellent Barrier: Provides a strong barrier against moisture, oxygen, and light, which is essential for preserving freshness and extending the shelf life of sensitive products.

* Good Heat Sealability: Forms strong, consistent seals, even at high speeds on packaging machinery.

* Aesthetic Appeal: The metallic finish offers a premium and attractive look to the packaging.

* Good Printability: The untreated surface allows for high-quality printing with vibrant colors and sharp images, enabling effective branding.

* Mechanical Strength: High tensile strength and tear resistance for durability.

* Cost-Effective: Often a more economical alternative to aluminum foil, while still offering excellent barrier properties.

* Recyclable: Many metallized BoPP films are designed to be recyclable, offering a more sustainable packaging solution.

Common Applications of BoPP Metallized HST Film:

Due to its combination of barrier properties, aesthetic appeal, and heat sealability, BoPP Metallized HST film is widely used in various packaging applications, especially in the food industry:

* Food Packaging:

* Snacks (chips, namkeen, biscuits, cookies, crackers)

* Confectionery (chocolates, candies)

* Dry foods (spices, tea, coffee, nuts, dry fruits)

* Frozen food pouches

* Bakery product wrapping

* Cereals

* Lamination: Used as an outer or inner layer in multi-layer laminates to enhance barrier, protection, and appearance.

* Labels and Wrappers: For products requiring branding and product information.

* Pouches and Bags: For various flexible packaging formats.

* Pharmaceutical Packaging: Where barrier protection is crucial.

* Cosmetic Packaging.

* Retail Packaging.

Manufacturers in India:

Several prominent manufacturers in India produce BoPP films, including metallized and heat-sealable variants. Some of the well-known names include:

* Jindal Poly Films Limited (JPFL)

* Cosmo Films

* Vacmet India Limited

* Satyendra Packaging Limited

* Chiripal Poly Films

* Polyplex Corporation Limited

* Raghav Polymers

These companies offer a wide range of BoPP films with varying properties and thicknesses to meet diverse packaging needs.

* BoPP (Biaxially Oriented Polypropylene): This is the base material. Polypropylene is a thermoplastic polymer. "Biaxially Oriented" means the film has been stretched in two directions (machine direction and transverse direction) during its manufacturing. This stretching process significantly enhances its mechanical properties, such as tensile strength, clarity, stiffness, and barrier properties.

* Metallized: A very thin layer of metal, typically aluminum, is deposited onto one side of the BoPP film. This metallization process gives the film a shiny, silver-like appearance and, more importantly, dramatically improves its barrier properties against moisture, oxygen, and light. This extended barrier helps to increase the shelf life of packaged products, especially food items.

* HST (Heat Sealable): This indicates that at least one side of the film can be sealed by applying heat and pressure. This is crucial for creating secure pouches, bags, and other packaging formats that maintain product integrity and prevent tampering. Often, one side is heat-sealable, while the other side is treated for printing or lamination.

Key Properties of BoPP Metallized HST Film:

* Excellent Barrier: Provides a strong barrier against moisture, oxygen, and light, which is essential for preserving freshness and extending the shelf life of sensitive products.

* Good Heat Sealability: Forms strong, consistent seals, even at high speeds on packaging machinery.

* Aesthetic Appeal: The metallic finish offers a premium and attractive look to the packaging.

* Good Printability: The untreated surface allows for high-quality printing with vibrant colors and sharp images, enabling effective branding.

* Mechanical Strength: High tensile strength and tear resistance for durability.

* Cost-Effective: Often a more economical alternative to aluminum foil, while still offering excellent barrier properties.

* Recyclable: Many metallized BoPP films are designed to be recyclable, offering a more sustainable packaging solution.

Common Applications of BoPP Metallized HST Film:

Due to its combination of barrier properties, aesthetic appeal, and heat sealability, BoPP Metallized HST film is widely used in various packaging applications, especially in the food industry:

* Food Packaging:

* Snacks (chips, namkeen, biscuits, cookies, crackers)

* Confectionery (chocolates, candies)

* Dry foods (spices, tea, coffee, nuts, dry fruits)

* Frozen food pouches

* Bakery product wrapping

* Cereals

* Lamination: Used as an outer or inner layer in multi-layer laminates to enhance barrier, protection, and appearance.

* Labels and Wrappers: For products requiring branding and product information.

* Pouches and Bags: For various flexible packaging formats.

* Pharmaceutical Packaging: Where barrier protection is crucial.

* Cosmetic Packaging.

* Retail Packaging.

Manufacturers in India:

Several prominent manufacturers in India produce BoPP films, including metallized and heat-sealable variants. Some of the well-known names include:

* Jindal Poly Films Limited (JPFL)

* Cosmo Films

* Vacmet India Limited

* Satyendra Packaging Limited

* Chiripal Poly Films

* Polyplex Corporation Limited

* Raghav Polymers

These companies offer a wide range of BoPP films with varying properties and thicknesses to meet diverse packaging needs.

| Type | Roll |

| Colour | Silver |

| Usage/application | Packaging |

| Thikness | 15-30 |

| Material | BOPP METLIZE |

| Roll Width | 35 inch |

| Country of Origin | Made in India |

Looking for "Metalized Heat Sealable Film" ?

Kilogram